私はこの薬に救われました。職場が変わって、ストレスを抱えるようになり、うつ病のような症状が出ていましたが、今では落ち着いています。悲観的な考えがなくなったので、とても過ごしやすいです。

左記クレジットカード、銀行振込、コンビニ決済に対応

更新日:2025/6/25

| 商品名 | ジェリフォルテ | フォンクセラ | ベネジスXR | サインバルタ・ジェネリック | スティリザン | トラザロン | セドキシル | レクサプロ・ジェネリック |

|---|---|---|---|---|---|---|---|---|

| 商品画像 |  |  |  |  |  |  |  |  |

| 特徴1 | ・免疫力の低下を防ぐ効果にも期待できる | ・国内処方されている抗うつ薬のジェネリック | ・神経伝達物質に影響を与えて気分をコントロールする | 先発薬サインバルタよりも安価に購入可 | ・不安や抑うつ症状、統合失調症などに効果的 | ・副作用がかなり抑えられており安全性が高い | ・慢性胃炎や心臓神経症にも効果が期待できる | 病院処方のレクサプロと同成分を配合 |

| 特徴2 | ・天然成分が精神的な負担を軽減する | ・従来のSSRIより副作用が少ないとされている | ・国内の抗うつ薬と同成分を配合している | 初めての服用に適した20mg錠あり | ・他の医薬品にも使われている成分なので信頼できる | ・眠気が起きるので睡眠障害にも使用可能 | ・筋肉をほぐして緊張型頭痛にも効果を発揮 | 初回向け5mg錠を選べる |

| 内容量 | 100錠 | 5mg28錠x1箱 | 37.5mg28錠x1箱 | 20mgx100錠 | 1mg30錠x1箱 | 50mgx100錠 | 1mg60錠x1箱 | 5mgx100錠 |

| 価格 | 2,860円 | 4,860円 | 3,560円 | 6,060円 | 3,860円 | 7,260円 | 6,560円 | 3,560円 |

プロザックは、アメリカの大手製薬メーカーであるイーライリリー(Eli Lilly)が製造を手がけている抗うつ剤です。

1988年に世に出て以降、現在に至るまで主要な抗うつ剤として用いられているため、実績や安心感を重視したい方におすすめです。

| メーカー | イーライリリー(Eli Lilly) |

|---|---|

| 有効成分 | 塩酸フルオキセチン |

| 効果 | 不安障害・うつ症状の改善(MDD) |

| 副作用 | 不眠や悪心など |

| 用法 | 毎日一定の時刻に1回分を服用 |

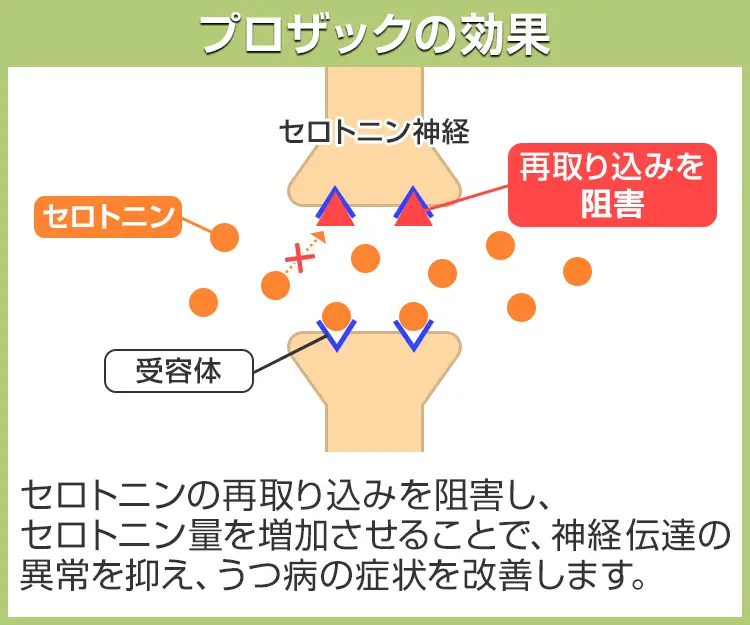

プロザックに有効成分として配合されているフルオキセチンは、選択的セロトニン再取り込み阻害薬(SSRI)に分類されます。興奮や不安を抑える神経伝達物質セロトニンの濃度を高めることで、抑うつ症状を改善させます。

プロザックには、1錠あたり20mgのフルオキセチンが配合されています。

| 個数 | 販売価格(1箱あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 1箱 | 5,360円 | 5,360円 | 160pt | 売り切れ |

| 2箱 | 4,480円 | 8,960円 | 268pt | 売り切れ |

| 4箱 | 4,115円 | 16,460円 | 493pt | 売り切れ |

①1万円以上で送料無料

1回の注文で10,000円以上だった場合、1,000円の送料が無料となります。

まとめ買いをすると1商品あたりのコストパフォーマンスが高くなるためおすすめです。

②プライバシー守る安心梱包

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

③100%メーカー正規品取り扱い

当サイトの商品は100%メーカー正規品となっており、第三者機関による鑑定も行っております。

商品の破損などがあった場合は再配送などにて対応させて頂きますので、ご連絡頂ければ幸いです。

④いつでも購入可能 処方箋不要

サイト上では24時間いつでもご注文を受けております。

また、お電話によるご注文も受け付けておりますのでネットが苦手な方はお気軽にどうぞ。

⑤商品到着100%

商品発送後はお荷物の追跡状況が分かる追跡番号をご案内させて頂きます。

郵便局には保管期限がありますのでご注意ください。

・自宅配達で不在だった場合の保管期限・・・16日間前後

・郵便局留めとした場合の保管期限・・・7~30日間

⑥コンビニ決済利用可能

ご近所のコンビニにていつでもお支払可能です。

セブンイレブンに限り店舗での機械操作を必要とせず、手続き完了後に表示されるバーコードや払込票番号をレジに提示することでお支払い頂けます。

プロザック 20mg28錠 x 4箱

16,460円

ポイント:493pt

10,000円以上購入で送料無料

売り切れ

私はこの薬に救われました。職場が変わって、ストレスを抱えるようになり、うつ病のような症状が出ていましたが、今では落ち着いています。悲観的な考えがなくなったので、とても過ごしやすいです。

飲んでも何が変わったのかわからない。自分には効目が弱いのかな。副作用は感じないから飲み続けられるけど、他の薬を試した方が良さそう。

プロザックは、気分を前向きにする作用がある薬です。うつ病や不安障害などで気分が落ち込んでいるときに、脳のセロトニンを調整して気持ちを安定させる働きがあります。

強迫性障害にも効果があるとされています。プロザックの服用で手洗いや確認などの繰り返し行動が減っていったという報告もあり、治療の選択肢として広く使われています。5週間以上続けることで治療効果があらわれることもあるので適切に継続することも大切です。

飲み始めてから4〜5週間であらわれることが多いです。焦らずに継続することで、少しずつ気分が安定してくることが期待されます。すぐに効かないからといって自己判断でやめないようにしましょう。

プロザックの服用で過食と嘔吐の回数が有意に減少したという報告があります。効果は服用1週目から現れ、16週にわたって継続して確認されています。完全にゼロになるわけではありませんが、大幅に減る人もいます。

プロザックは1日1回、朝に水などで飲みます。最初は少ない量から始めて、様子を見ながら徐々に増やすことがあります。決められた時間に毎日継続して飲むことで、効果が安定してあらわれやすくなります。

フルオキセチンは基本的に1日1回の服用です。効果や副作用のバランスを見ながら、20mg以上の量が必要な場合は朝と昼に分けて2回にすることもあります。自分で変えず、必ず医師に確認してください。

フルオキセチンは、食事の影響をあまり受けない薬なので、食後でも空腹時でも服用できます。ただし、胃への負担を避けたい場合は食後に飲むと安心です。医師の指示に従うのが基本です。

うつの症状が重くても最初は少ない量から始めるのが一般的です。様子を見ながら数週間後に増量するかを判断します。早く効かせたい気持ちがあっても、焦らず段階的に調整するのが安全です。

高齢者は薬の代謝が遅くなることがあります。その結果、薬の成分が体に長く残り続けることになって低ナトリウム血症や眠気などの副作用が出やすくなることがあります。そのため、用量の調整や慎重な経過観察が必要とされています。

眠気(傾眠)が副作用として報告されています。日中の眠気が強い場合は、服用時間の変更などで対応できることもあるので、日常生活に支障がでてしまったりしている場合は相談するようにしましょう。

プロザックを飲むときは、副作用や飲み合わせに注意が必要です。眠気や不眠、出血しやすくなることがあるので、日常生活にも気を配ることが大切です。医師の指示を守って、無理のない服用を心がけてください。

プロザックはてんかんの持病がある方や、QT延長のある方、MAOIを服用中の方などには使用できない場合があります。安全に使うためにも、服用前に必ず医師と相談することが必要です。

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 20~80mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 20~60mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 10~60mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 20~80mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | フルオキセチンとして20~50mg オランザピンとして5~12.5mg |

| 服用のタイミング | 夕食後または就寝前 |

| 服用間隔 | 24時間 |

| 頻度が高いもの | 頻度が低いもの | 稀なもの | |

| 身体全体 | 悪寒 | 自殺未遂 | 急性腹部症候群、光線過敏症反応 |

| 心臓血管系 | 動悸 | 不整脈、低血圧 | |

| 消化器系 | 嚥下困難、胃炎、胃腸炎、下血、胃潰瘍 | 血性下痢、十二指腸潰瘍、食道潰瘍、胃腸出血、吐血、肝炎、消化性潰瘍、胃潰瘍出血 | |

| 血液およびリンパ系 | 斑状出血、稀:点状出血、紫斑 | ||

| 検査 | QT間隔の延長(QT c F ≥450ミリ秒) | ||

| 神経系 | 情緒不安定 | アカシジア、運動失調、平衡障害1、歯ぎしり1、頬舌症候群、離人感、多幸感、筋緊張亢進、性欲亢進、ミオクローヌス、妄想性反応、妄想 | |

| 呼吸器系 | 喉頭浮腫 | ||

| 皮膚および付属器 | 脱毛症、紫斑 | ||

| 特殊感覚 | 味覚異常 | 散瞳 | |

| 泌尿生殖器系 | 排尿障害 | 排尿困難、婦人科出血 |

本製品は海外製のため、期限表記が日本と異なる場合がございます。

パッケージ裏面や側面、シートなどに以下のような表記がされています。

| EXP | 使用期限 例:EXP 12/2025→2025年12月まで使用可 |

|---|---|

| MFG または MFD | 製造日 例:MFG 03/2023 |

| BEST BEFORE | 品質が最も安定している目安日 |

※国や製品により日付の並び(例:月/年、日/月/年)が異なる場合がありますのでご注意ください

EXP(Expiry Date) の表記がなく、MFG または MFDしか記載がないケースがあります。

この場合は MFG(MFD) から2~3年が使用期限の目安です。

※「LOT」や「BATCH」の表記は製造番号であり期限ではありません。

パッケージ例となります。

商品やご注文単位によってはシート単位でのお届けとなる場合が御座います。

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

この薬を飲むと安心します。依存はよくないですけど、どうしても気持ちが不安定な時は、この薬の力を借りようと思います。

私はこの薬に救われました。職場が変わって、ストレスを抱えるようになり、うつ病のような症状が出ていましたが、今では落ち着いています。悲観的な考えがなくなったので、とても過ごしやすいです。

効き目には満足してる。だけど、カプセルがちょと大きい。私には飲みにくいです。

飲んでも何が変わったのかわからない。自分には効目が弱いのかな。副作用は感じないから飲み続けられるけど、他の薬を試した方が良さそう。

飲むと気持ち悪くなっちゃうので効果を実感するどころじゃないです。コレは私には合ってないですね。

商品口コミの投稿は会員のみ行えるようになっております。

お手数ですが会員ログインの上でご投稿頂きますようお願いいたします。

口コミをご投稿頂いたお客様にはポイントをプレゼントさせて頂いております。

文章のみであれば100ポイント、文章+写真付きのものは300ポイントをプレゼントさせて頂きます。

規約や詳細などはこちらをご確認くださいませ。