左記クレジットカード、銀行振込、コンビニ決済に対応

更新日:2025/6/13

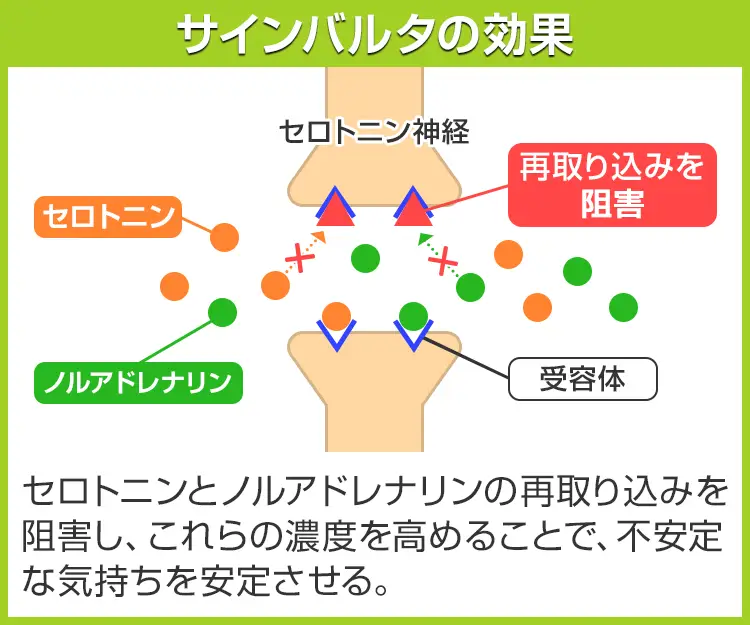

サインバルタは、SNRI(セロトニン・ノルアドレナリン再取り込み阻害薬)に分類される抗うつ剤です。

有効成分は痛みにも効くことが判明しており、糖尿病性神経障害に伴う疼痛や慢性腰痛症などの症状緩和に用いることもできます。

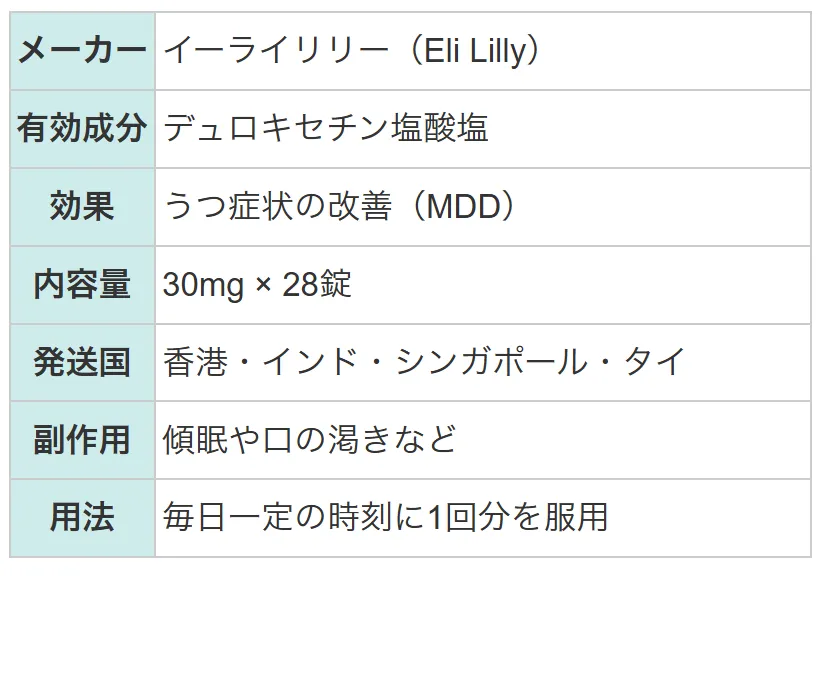

| メーカー | イーライリリー(Eli Lilly) |

|---|---|

| 有効成分 | デュロキセチン塩酸塩 |

| 効果 | うつ症状の改善(MDD) |

| 副作用 | 傾眠や口の渇きなど |

| 用法 | 毎日一定の時刻に1回分を服用 |

サインバルタに含有されているデュロキセチンは、脳内において、神経を落ち着かせる作用があるセロトニンおよびノルアドレナリンという神経伝達物質の濃度を高める作用があります。

1錠あたり30mgのデュロキセチンが配合されています。

| 個数 | 販売価格(1錠あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 28錠 | 209円 | 5,860円 | 175pt | |

| 56錠 | 170円 | 9,560円 | 286pt | |

| 84錠 | 154円 | 12,960円 | 388pt |

| 個数 | 販売価格(1錠あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 28錠 | 255円 | 7,160円 | 214pt | 売り切れ |

| 56錠 | 222円 | 12,460円 | 373pt | 売り切れ |

| 84錠 | 197円 | 16,560円 | 496pt | 売り切れ |

①1万円以上で送料無料

1回の注文で10,000円以上だった場合、1,000円の送料が無料となります。

まとめ買いをすると1商品あたりのコストパフォーマンスが高くなるためおすすめです。

②プライバシー守る安心梱包

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

③100%メーカー正規品取り扱い

当サイトの商品は100%メーカー正規品となっており、第三者機関による鑑定も行っております。

商品の破損などがあった場合は再配送などにて対応させて頂きますので、ご連絡頂ければ幸いです。

④いつでも購入可能 処方箋不要

サイト上では24時間いつでもご注文を受けております。

また、お電話によるご注文も受け付けておりますのでネットが苦手な方はお気軽にどうぞ。

⑤商品到着100%

商品発送後はお荷物の追跡状況が分かる追跡番号をご案内させて頂きます。

郵便局には保管期限がありますのでご注意ください。

・自宅配達で不在だった場合の保管期限・・・16日間前後

・郵便局留めとした場合の保管期限・・・7~30日間

⑥コンビニ決済利用可能

ご近所のコンビニにていつでもお支払可能です。

セブンイレブンに限り店舗での機械操作を必要とせず、手続き完了後に表示されるバーコードや払込票番号をレジに提示することでお支払い頂けます。

サインバルタ 30mg x 28錠

5,860円

ポイント:175pt

10,000円以上購入で送料無料

在庫あり

サインバルタは「飲み始めて数週間で気分の落ち込みが緩和される緩やかな立ち上がり」「不安感や身体の痛みが軽減し日常生活が楽になる」「30mgから始められ段階的に増量できるので服用しやすい」「初期の吐き気や眠気、頭痛などの副作用」「通販で入手できる利便性」「通院不要で継続しやすい」「価格が国内処方の約3分の1とコスパ良好」といった点が口コミで多く言及されています。

副作用はほとんど数日で慣れ、継続利用しやすい点も支持されています。

ユーザーの多くは「継続2週目あたりで心が軽くなった」「不安感がスーッと引いて外出が苦痛でなくなった」「モヤモヤした気持ちがなくなり仕事に意欲が湧いた」と、徐々にではありますが確かな気分安定を実感しています。

うつ症状だけでなく慢性痛やイライラにも効果を感じる声が寄せられています。

「初日は30mg、体調を見ながら45mg→60mgへと段階的に増やせる」「半錠ずつ分割して服用できる」「朝服用で眠気が出る場合は夜に変更可能」など、自分の体調に合わせやすい点が好評です。

ピルカッターで簡単に割って調整できるため、無理なく最適量を見つけられるとの声が多数あります。

「初期に軽い吐き気や胸焼け、胃もたれを感じる」「飲み始め数日で眠気やだるさが出ることがある」「頭痛やめまいがわずかに見られる」という報告が目立ちます。

ただし多くは1~2週間で慣れ、「食後服用で吐き気が減った」「就寝前に飲むと眠気が気にならない」といった対策が効果的とされています。安心して継続できる範囲と言えるでしょう。

脳の中にあるセロトニンやノルアドレナリンという気分を安定させる神経伝達物質の働きを高めることで、うつ病の気分の落ち込みや意欲の低下を改善します。飲み続けることで、徐々に気分が安定し、毎日の生活が少しずつ楽に感じられるようになります。

糖尿病によって神経が傷んだときに起こる痛みやしびれをやわらげる効果があります。飲み続けることで神経の痛みが少しずつ軽減し、日常生活の不快感が和らぐことが期待されています。

慢性的に続く腰の痛みにも効果がある薬です。通常の痛み止めだけでは効果が十分でない場合に、痛みの感じ方を調整することで、腰の重だるさやつらさを軽減する役割を果たします。

一般的に1〜2週間ほどで効果を感じ始める人が多いとされています。気分の落ち込みや痛みの軽減が少しずつ現れてくるのが目安です。

サインバルタは、通常1日1回、朝または昼に飲む薬です。食事と関係なく飲むことができますが、決まった時間に毎日忘れずに飲むことで、安定した効果が期待できます。

サインバルタは朝食後の服用が指定されています。そのため、朝食の後に飲むようにしてください。朝食を食べる習慣がない場合でも、軽く何かを食べてから服用するようにしてください。

サインバルタを飲み忘れた場合は、気づいたときにすぐ1回分を飲みましょう。ただし、次の飲む時間が近いときは1回分を飛ばして、いつも通りに戻してください。2回分をまとめて飲んではいけません。

サインバルタは、自己判断で急にやめると、めまいや吐き気、不安感などの離脱症状が出ることがあります。やめるときは必ず先生に相談しながら、少しずつ減らす必要があります。

サインバルタでは吐き気、口の渇き、眠気、めまい、便秘などの副作用が起こることがあります。多くは軽いものですが、症状がつらいときは無理せず先生に相談しましょう。

まれにサインバルタで気分が不安定になったり、自殺念慮が出ることがあると報告されています。気持ちが沈んだり、不安感が強くなった場合は、すぐに先生に相談してください。

めまい、吐き気、不安感、頭痛などの離脱症状が出ることがあります。中止するときは必ず医師の指示に従いながら、徐々に服用する量を減らしていく必要があります。

サインバルタでは、体重増加の報告もあります。ただし、頻度自体は高くありません。すべての人に起こるわけではありませんが、体重の変化に気づいたら先生に相談することをおすすめします。

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 20~60mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 1日の服用回数 | 1回 |

|---|---|

| 1日の服用量 | 20~60mg |

| 服用のタイミング | 朝食後 |

| 服用間隔 | 24時間 |

| 商品名 | コントミン・ジェネリック | レクサプロ・ジェネリック | エビリファイ | シタロプラム | クロフラニール | アロー | ブプラパン |

|---|---|---|---|---|---|---|---|

| 商品画像 |  |  |  |  |  |  |  |

| 特徴1 | うつ病や統合失調症に効果を発揮する | 病院処方のレクサプロと同成分を配合 | 不安感や気分の落ち込みを解消する | ・効果の持続時間が長い | ・大容量で長期服用に最適 | ・SSRI(SNRI)で効かない場合に有効な抗うつ薬 | ・アメリカでは広く流通している抗うつ剤 |

| 特徴2 | 不眠症の改善にも使える | 初回向け5mg錠を選べる | うつ病と統合失調症に効果を発揮 | ・レクサプロ・ジェネリックなどの成分の元となった成分を配合 | ・先発薬アナフラニールより低価格で購入できる | ・作用が強いので高い改善効果を期待できる | ・禁煙の成功も高める |

| 内容量 | 100mgx100錠 | 5mgx100錠 | 5mg28錠x1箱 | 20mgx28錠 | 10mgx100錠 | 10mgx100錠 | 300mg30錠x1箱 |

| 価格 | 2,700円 | 3,560円 | 4,760円 | 4,560円 | 2,960円 | 3,260円 | 5,060円 |

| 5%以上 | 1〜5%未満 | 1%未満 | 頻度不明 | |

| 過敏症 | 発疹、そう痒、蕁麻疹 | 接触性皮膚炎、光線過敏反応、血管浮腫、皮膚血管炎 | ||

| 全身症状 | 倦怠感 | ほてり、発熱、悪寒、脱水、脱力感 | ||

| 精神神経系 | 傾眠(24.3%)、頭痛、めまい | 不眠、立ちくらみ、しびれ感、振戦、浮遊感 | あくび、焦燥感、気分高揚、注意力障害、錐体外路症状、不安、異常夢(悪夢を含む)、頭がぼーっとする、性欲減退、躁病反応、錯感覚、無感情、味覚異常 | 激越、オーガズム異常、嗜眠、睡眠障害、歯軋り、失見当識、攻撃性、怒り、歩行障害、開口障害、下肢静止不能症候群、異常感 |

| 消化器 | 悪心(22.4%)、食欲減退、口渇(12.8%)、便秘(12.4%)、下痢 | 腹部痛、嘔吐、腹部膨満感、腹部不快感、消化不良、胃炎 | 口内炎、歯痛、胃腸炎、咽頭不快感 | 咽頭炎、咽喉緊張、口臭、嚥下障害、顕微鏡的大腸炎 |

| 感覚器 | 耳鳴 | 視調節障害、眼乾燥、霧視、耳痛 | 散瞳、緑内障 | |

| 循環器 | 動悸、頻脈、血圧上昇 | 起立性低血圧、上室性不整脈、失神 | ||

| 肝臓 | AST上昇、ALT上昇、γ-GTP上昇、総ビリルビン上昇、Al-P上昇、LDH上昇 | |||

| 血液 | ヘモグロビン減少、赤血球減少、ヘマトクリット減少、鼻出血 | 異常出血(斑状出血、胃腸出血等)、白血球減少 | ||

| 筋・骨格系 | 背部痛、関節痛、筋痛、肩こり、筋痙攣 | 筋緊張 | ||

| 泌尿器・生殖器 | 排尿困難 | 性機能異常(月経異常、射精障害、勃起障害等)、排尿障害、血中クレアチニン上昇、BUN上昇、頻尿、尿中アルブミン/クレアチニン比上昇、尿流量減少 | 多尿、閉経期症状、精巣痛 | |

| 代謝・内分泌 | 高血糖、トリグリセリド上昇、総コレステロール上昇、尿中蛋白陽性 | 血中カリウム減少 | 甲状腺機能低下、低ナトリウム血症、乳汁漏出症、高プロラクチン血症、血中カリウム上昇 | |

| その他 | 発汗、体重減少、体重増加、CK(CPK)上昇 | 浮腫、冷感、熱感、呼吸苦、胸痛、冷汗、咳嗽 |

本製品は海外製のため、期限表記が日本と異なる場合がございます。

パッケージ裏面や側面、シートなどに以下のような表記がされています。

| EXP | 使用期限 例:EXP 12/2025→2025年12月まで使用可 |

|---|---|

| MFG または MFD | 製造日 例:MFG 03/2023 |

| BEST BEFORE | 品質が最も安定している目安日 |

※国や製品により日付の並び(例:月/年、日/月/年)が異なる場合がありますのでご注意ください

EXP(Expiry Date) の表記がなく、MFG または MFDしか記載がないケースがあります。

この場合は MFG(MFD) から2~3年が使用期限の目安です。

※「LOT」や「BATCH」の表記は製造番号であり期限ではありません。

パッケージ例となります。

商品やご注文単位によってはシート単位でのお届けとなる場合が御座います。

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

両足の裏のジンジン、ピリピリする痛みで夜も眠れませんでした。この方法に変えてから、痛みが半分以下になった感覚です。おかげで睡眠不足も解消し、日中の活動も楽になりました。歩くのが苦痛でなくなりました。

常に漠然とした不安感があり、動悸や息苦しさもありました。このケアを始めてから、不安感がスーッと引き、落ち着いて過ごせる時間が増えました。外出も以前より怖くなくなり、世界が広がった気がします。

何も手につかず、ただ横になっているだけの日々から、このケアで抜け出せました。少しずつですが、朝起きるのが辛くなくなり、仕事への意欲も戻ってきました。気分の落ち込みも軽くなり、未来に希望が持てそうです。

何かしら副作用は感じるかもしれないと思っていましたが、飲んでみると何も感じませんでした。そのまま続けていると憂鬱な気分が薄れていき、精神的に楽になってきています。薬が私に合っていて良かったです。

届いたのは注文してから2週間後だけど、通院しなくても薬が買えるのは便利。真夏だと外に出る事さえめんどくさいから助かる。

商品口コミの投稿は会員のみ行えるようになっております。

お手数ですが会員ログインの上でご投稿頂きますようお願いいたします。

口コミをご投稿頂いたお客様にはポイントをプレゼントさせて頂いております。

文章のみであれば100ポイント、文章+写真付きのものは300ポイントをプレゼントさせて頂きます。

規約や詳細などはこちらをご確認くださいませ。