なんとかお金をかけずに自力で禁煙しようと思いましたが無理でした(笑)病院へは行きたくないのでこちらを買ってみましたが、確かに前よりタバコが不味くなったように感じる。。。だからか本数も若干減ってきました。完全禁煙できるまではしばらくかかりそうですが、追加購入せずに禁煙できることを目標にします。

左記クレジットカード、銀行振込、コンビニ決済に対応

更新日:2025/6/15

| 個数 | 販売価格(1錠あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 100錠 | 69円 | 6,960円 | 208pt | |

| 200錠 | 64円 | 12,960円 | 388pt | |

| 300錠 | 63円 | 18,960円 | 568pt |

①1万円以上で送料無料

1回の注文で10,000円以上だった場合、1,000円の送料が無料となります。

まとめ買いをすると1商品あたりのコストパフォーマンスが高くなるためおすすめです。

②プライバシー守る安心梱包

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

③100%メーカー正規品取り扱い

当サイトの商品は100%メーカー正規品となっており、第三者機関による鑑定も行っております。

商品の破損などがあった場合は再配送などにて対応させて頂きますので、ご連絡頂ければ幸いです。

④いつでも購入可能 処方箋不要

サイト上では24時間いつでもご注文を受けております。

また、お電話によるご注文も受け付けておりますのでネットが苦手な方はお気軽にどうぞ。

⑤商品到着100%

商品発送後はお荷物の追跡状況が分かる追跡番号をご案内させて頂きます。

郵便局には保管期限がありますのでご注意ください。

・自宅配達で不在だった場合の保管期限・・・16日間前後

・郵便局留めとした場合の保管期限・・・7~30日間

⑥コンビニ決済利用可能

ご近所のコンビニにていつでもお支払可能です。

セブンイレブンに限り店舗での機械操作を必要とせず、手続き完了後に表示されるバーコードや払込票番号をレジに提示することでお支払い頂けます。

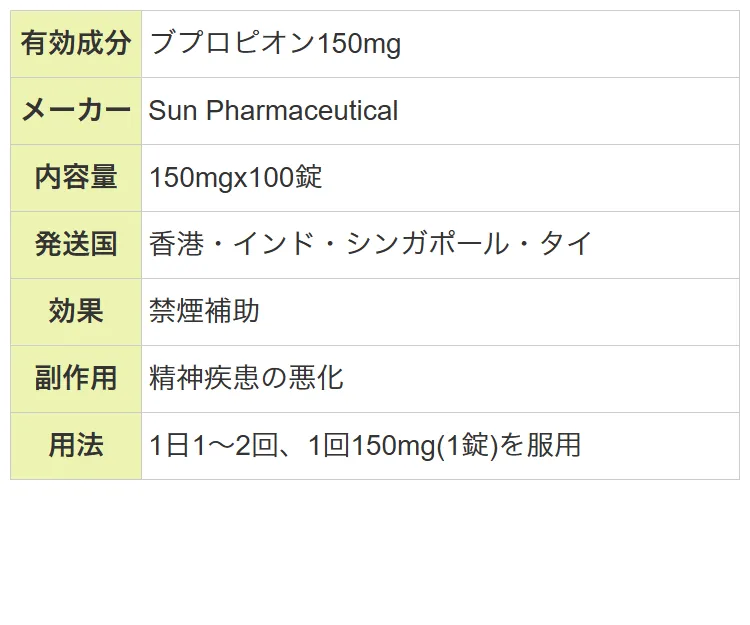

ブプロンSR 150mg x 100錠

6,960円

ポイント:208pt

10,000円以上購入で送料無料

在庫あり

なんとかお金をかけずに自力で禁煙しようと思いましたが無理でした(笑)病院へは行きたくないのでこちらを買ってみましたが、確かに前よりタバコが不味くなったように感じる。。。だからか本数も若干減ってきました。完全禁煙できるまではしばらくかかりそうですが、追加購入せずに禁煙できることを目標にします。

ニコチンの成分が含まれていないということなので、安心して服用できると思い購入しました。ですが、私には合っていないようで、タバコを吸いたい欲がなかなか消えてくれません。

禁煙治療薬の副作用には個人差があります。全く副作用症状があらわれない方もいますが、強い副作用があらわれる方もいます。ただ、一般的に酷い副作用があらわれる可能性が高いというものではないので、副作用自体は強いというものではないと考えられます。

個人差はありますが、薬の服用を継続することで煙草を不味く感じるようになって、次第に喫煙に対する欲求を下げる治療薬なので、そうした状態は正常と考えられます。

禁煙治療薬チャンピックスはうつ病治療薬との併用ができない場合があります。また、うつ病を患っている場合、それが悪化してしまむおそれもあるためです。

服用自体はしなくても問題はありません。ただし、禁煙治療薬は喫煙欲を抑えるための治療薬なのでそれを我慢できるかどうかという点が問題となります。我慢できる場合は問題ないですが、そうでない場合には継続しての服用が推奨されます。

チャンピックスは水で服用するため、基本的に味を感じるといったことはないと考えられます。粉末にして服用したりすれば別ですが、そうした用法は推奨されていません。適切な用法用量を守ってご使用ください。

禁煙治療薬の併用禁忌や併用注意に低用量ピルは指定されていません。そのため、低用量ピルとの併用は問題がないと考えられます。自己判断で不安がある場合には、病院や薬局などで相談するようにしてください。

| 1日の服用回数 | 1~2回 |

|---|---|

| 1回の服用量 | 150mg |

| 服用のタイミング | 早朝、または就寝前を除いたタイミング |

| 服用間隔 | 8時間以上 |

| 商品名 | ニコテックス | ニコレットパッチ | ニコチネル | ハビトロールチューイングガム | ニコレットガム | ニコシップガム | ブプロバン | チャンピックス禁煙フルセット |

|---|---|---|---|---|---|---|---|---|

| 商品画像 |  |  |  |  |  |  |  |  |

| 特徴1 | ・ガムのため手軽に禁煙を進めることができる | ・時間をかけて体内に少しずつ吸収される | ・身体に貼って徐々に禁煙に導くパッチ | ・タバコと同じニコチンが含まれている | ・知名度が高い禁煙補助薬 | ・手軽に摂取して禁煙を成功しやすくできる | ・ニコチン不足によるイライラを効果的に抑えられる | ・無理なく禁煙できる補助薬 |

| 特徴2 | ・ニコチンを含んでいるため禁断症状も抑えられる | ・実効性のある禁煙スケジュールを立てやすい | ・貼るだけだから使い勝手がいい | ・禁煙時の離脱症状を防ぐ | ・離脱症状を緩和して効果的に禁煙できる | ・ニコレットガムと同等の効果を期待できる | ・抗うつ薬としての効果にも期待できる | ・治療の継続ならチャンピックス・2週間パック |

| 内容量 | 2mgx9粒 | (ステップ1)25mg7枚x1箱 | 21mgx21枚 | 2mg(ミント)x204粒 | 2mg(アイスホワイト)105粒x1箱 | 4mg10粒x1箱 | 150mg30錠x1箱 | 0.5mg+1mgx165錠 |

| 価格 | 2,260円 | 5,860円 | 11,260円 | 7,060円 | 6,560円 | 2,260円 | 4,360円 | 32,800円 |

本製品は海外製のため、期限表記が日本と異なる場合がございます。

パッケージ裏面や側面、シートなどに以下のような表記がされています。

| EXP | 使用期限 例:EXP 12/2025→2025年12月まで使用可 |

|---|---|

| MFG または MFD | 製造日 例:MFG 03/2023 |

| BEST BEFORE | 品質が最も安定している目安日 |

※国や製品により日付の並び(例:月/年、日/月/年)が異なる場合がありますのでご注意ください

EXP(Expiry Date) の表記がなく、MFG または MFDしか記載がないケースがあります。

この場合は MFG(MFD) から2~3年が使用期限の目安です。

※「LOT」や「BATCH」の表記は製造番号であり期限ではありません。

パッケージ例となります。

商品やご注文単位によってはシート単位でのお届けとなる場合が御座います。

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

人生で3回禁煙チャレンジしてきましたがことごとく失敗。でも、今回は妻が妊娠したので本気で禁煙しようと考えてます。本当は禁煙外来へ行きたいのですが、仕事の都合上通院が難しいのでこちらでお薬のみ購入させてもらいました。まだ届いてはおりませんが、今からしっかり禁煙できるように気持ちの準備をしています。

なんとかお金をかけずに自力で禁煙しようと思いましたが無理でした(笑)病院へは行きたくないのでこちらを買ってみましたが、確かに前よりタバコが不味くなったように感じる。。。だからか本数も若干減ってきました。完全禁煙できるまではしばらくかかりそうですが、追加購入せずに禁煙できることを目標にします。

禁煙二ヶ月目に突入です。今回は初めて禁煙治療薬を使った禁煙になりますが、何もなしで禁煙するのと比べると圧倒的にいけそう感があります。もちろん禁断症状はあるのですがお薬のお陰でかなり軽減されています。以前は何もなしで禁煙した時はあっという間に誘惑に負けて吸ってしまいましたが、今回は我慢できているので薬の力はかなり大きいと思います。

禁煙(ほぼ)成功報告です!ブプロンSRを飲み始めて半年ほどですが、最後のタバコから5ヶ月ほど経ちました。今でもまったく喫煙欲求がないわけではないですが、これまでの半年が無駄になると思うと我慢できるレベルです。禁煙をきっかけにジョギングを始めたので、健康になっていく自分がちょっと好きになりつつもあります。あとは周りの喫煙者の戻ってこいオーラをなんとかしたいです笑

妻が妊娠したのでこれをきっかけに禁煙にチャレンジします。禁煙は自分の意志だけではかなり難しそうなので薬の力を頼ってなんとか成功させます。薬が届くまでは吸う本数を減らして体の準備も進めておきます。(微妙な減煙に意味があるのかわかりませんが)

商品口コミの投稿は会員のみ行えるようになっております。

お手数ですが会員ログインの上でご投稿頂きますようお願いいたします。

口コミをご投稿頂いたお客様にはポイントをプレゼントさせて頂いております。

文章のみであれば100ポイント、文章+写真付きのものは300ポイントをプレゼントさせて頂きます。

規約や詳細などはこちらをご確認くださいませ。