一気に50錠も買えて3,000円もしないのでコストパフォーマンスがいいです。家から出なくても薬が買えるなんて本当に助かるので、これからもお世話になります。

左記クレジットカード、銀行振込、コンビニ決済に対応

更新日:2025/4/25

| 個数 | 販売価格(1錠あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 50錠 | 59円 | 2,960円 | 88pt | |

| 100錠 | 37円 | 3,760円 | 112pt | |

| 150錠 | 35円 | 5,260円 | 157pt |

①1万円以上で送料無料

1回の注文で10,000円以上だった場合、1,000円の送料が無料となります。

まとめ買いをすると1商品あたりのコストパフォーマンスが高くなるためおすすめです。

②プライバシー守る安心梱包

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

③100%メーカー正規品取り扱い

当サイトの商品は100%メーカー正規品となっており、第三者機関による鑑定も行っております。

商品の破損などがあった場合は再配送などにて対応させて頂きますので、ご連絡頂ければ幸いです。

④いつでも購入可能 処方箋不要

サイト上では24時間いつでもご注文を受けております。

また、お電話によるご注文も受け付けておりますのでネットが苦手な方はお気軽にどうぞ。

⑤商品到着100%

商品発送後はお荷物の追跡状況が分かる追跡番号をご案内させて頂きます。

郵便局には保管期限がありますのでご注意ください。

・自宅配達で不在だった場合の保管期限・・・16日間前後

・郵便局留めとした場合の保管期限・・・7~30日間

⑥コンビニ決済利用可能

ご近所のコンビニにていつでもお支払可能です。

セブンイレブンに限り店舗での機械操作を必要とせず、手続き完了後に表示されるバーコードや払込票番号をレジに提示することでお支払い頂けます。

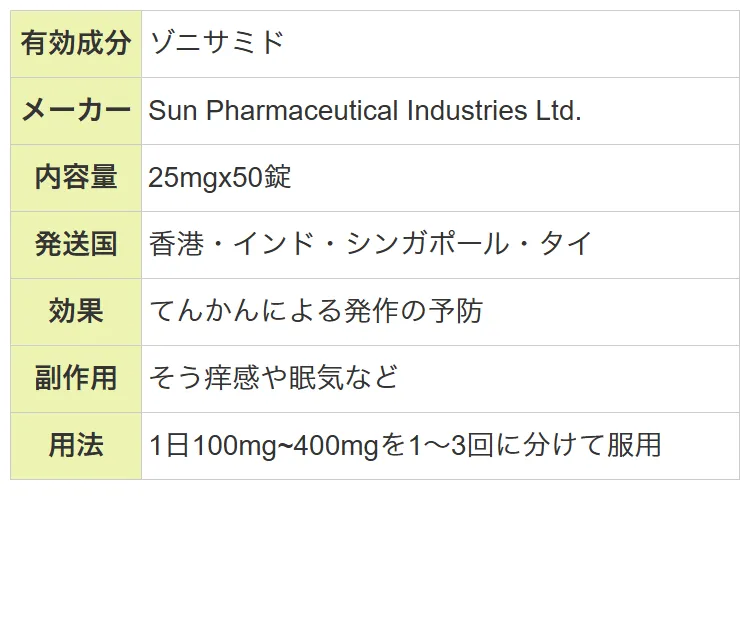

ゾニセップ 25mg x 50錠

2,960円

ポイント:88pt

10,000円以上購入で送料無料

在庫あり

一気に50錠も買えて3,000円もしないのでコストパフォーマンスがいいです。家から出なくても薬が買えるなんて本当に助かるので、これからもお世話になります。

思ったよりも副作用がきついかも。自分に合う薬が他にもあるかもしれないから探してみる。

てんかん薬の中には、副作用として倦怠感などがあらわれるものがあります。そのため、服用する薬によっては倦怠感を感じる可能性があります。あまりにも症状が酷いといった場合には、服用する薬の変更の相談などを行うようにしましょう。

てんかん薬の種類の中には、毛が薄くなるといったものはあります。逆に濃くなる種類の治療薬っていうものはないと考えられます。そのため、毛が濃くなったという場合には、てんかん薬以外の何か白が原因と考えられます。

てんかん薬を多量に服用したりした場合には、記憶力に影響を及ぼす可能性があったりします。ですが、適切にてんかん薬を使った場合にはそのリスクはほとんどないため、適切な用法用量を守って服用するようにしてください。

てんかんの場合に運転免許を取得するには、薬の服用は関係ありません。運転に支障があるような発作が数年にわたってない場合に取得できるとされているため、適切な治療を行い長期に渡って発作などが起きていない場合には取得することは可能といえます。

妊娠すること自体は可能ですが、催奇性の高い薬の場合はその分だけ奇形などのリスクは高まってしまいます。そのため、妊娠を希望する場合以外は適切な避妊を行う必要があります。また妊娠を希望する場合には、事前に医師に相談して妊娠とてんかん治療を両立することができる薬への変更などを行うことが重要になります。

治療薬の中止や再開を自己判断で行うのは大きなリスクがあります。医師と相談した上で適切な用法用量を守ってご使用ください。そのため、再開する場合であっても自己判断で行うのではなくまずは相談するようにしてください。

| 1日の服用回数 | 1~3回 |

|---|---|

| 1回の服用量 | 33~200mg |

| 服用のタイミング | 指定なし |

| 服用間隔 | 24時間以上 |

| 商品名 | (Emre Ecza)マイソリン | バルパリン | ブリバゼン | ラミトール | ラミクタール | ジファントイン-Z25 | マイソリン |

|---|---|---|---|---|---|---|---|

| 商品画像 |  |  |  |  |  |  |  |

| 特徴1 | ・塩化物イオンの流入を促進 | ・脳神経の興奮を鎮める | ・てんかんの部分発作を予防 | ・新薬のラミクタールより安価で購入可能 | ・治療困難なレノックス・ガストー症候群に有効 | ・様々なタイプのてんかんに有効 | ・塩化物イオンの通り道を広げる |

| 特徴2 | ・神経の過剰な興奮を抑制 | ・躁病の治療や片頭痛の予防にも有効 | ・脳内の異常な電気活動を抑制 | ・双極性障害やてんかんの治療や発作防止にも有効 | ・海外では双極性障害の第一選択薬 | ・脳内の興奮を鎮めててんかん発作を予防 | ・神経の興奮を抑制する |

| 内容量 | 250mg30錠x1箱 | 200mg150錠x1箱 | 25mg100錠x1箱 | 25mgx100錠 | 25mgx30錠 | 50錠x1箱 | 250mg300錠x1箱 |

| 価格 | 4,660円 | 6,060円 | 6,260円 | 4,360円 | 4,760円 | 4,360円 | 11,760円 |

本製品は海外製のため、期限表記が日本と異なる場合がございます。

パッケージ裏面や側面、シートなどに以下のような表記がされています。

| EXP | 使用期限 例:EXP 12/2025→2025年12月まで使用可 |

|---|---|

| MFG または MFD | 製造日 例:MFG 03/2023 |

| BEST BEFORE | 品質が最も安定している目安日 |

※国や製品により日付の並び(例:月/年、日/月/年)が異なる場合がありますのでご注意ください

EXP(Expiry Date) の表記がなく、MFG または MFDしか記載がないケースがあります。

この場合は MFG(MFD) から2~3年が使用期限の目安です。

※「LOT」や「BATCH」の表記は製造番号であり期限ではありません。

パッケージ例となります。

商品やご注文単位によってはシート単位でのお届けとなる場合が御座います。

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

いつも利用してる。通院しなくてもいいからめちゃくちゃ便利。けど、薬が届くのが早かったり、遅かったり、毎回バラバラだから余裕を持って注文しておいた方がいいよ。

少しずつ効き目を実感しています。副作用に関しては少し食欲が落ちる程度です。重度な副作用ではないので、これからも服用を続けていきます。

仕事が忙しいと病院に行く時間が作れませんし、飲む薬が無くなってしまっては困るので、ココロ薬局さんで注文しました。エクセグラン錠の海外版ではありますが、飲んでも副作用は感じません。安全性は高いようなので安心しました。

思ったよりも副作用がきついかも。自分に合う薬が他にもあるかもしれないから探してみる。

届くのは遅いけど、薬が無くなる前に注文しておけば大丈夫。何より、薬の値段が安いから助かる。

商品口コミの投稿は会員のみ行えるようになっております。

お手数ですが会員ログインの上でご投稿頂きますようお願いいたします。

口コミをご投稿頂いたお客様にはポイントをプレゼントさせて頂いております。

文章のみであれば100ポイント、文章+写真付きのものは300ポイントをプレゼントさせて頂きます。

規約や詳細などはこちらをご確認くださいませ。