飲むタイプのものは副作用が強すぎて利用することが出来ませんでした。どうやら血圧を下げる薬との併用はダメだったみたいです。でもヒムコリンは他の薬との飲み合わせなどは気にする必要がないので安心です。もちろん副作用も出ません。もっと早くヒムコリンを使ってれば良かったです。

左記クレジットカード、銀行振込、コンビニ決済に対応

更新日:2025/6/22

ヒムコリンは、血行改善による勃起力向上に加えて、性欲向上も期待できるサプリメントです。

インドの伝統医学アーユルヴェーダの考え方に基づいて配合された成分が、男性機能の向上をサポートします。

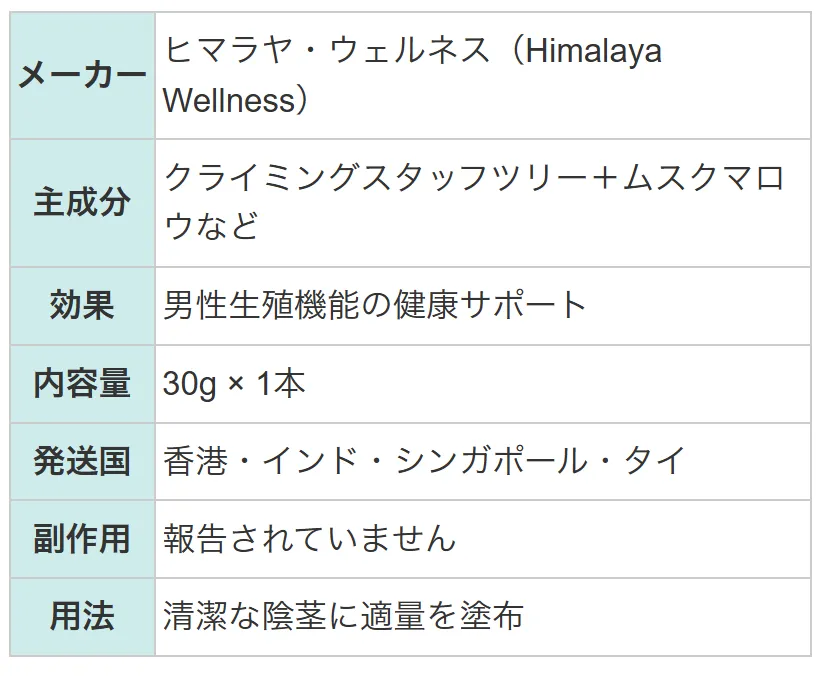

| メーカー | ヒマラヤ・ウェルネス(Himalaya Wellness) |

|---|---|

| 主成分 | クライミングスタッフツリー+ムスクマロウなど |

| 効果 | 男性生殖機能の健康サポート |

| 副作用 | 報告されていません |

| 用法 | 清潔な陰茎に適量を塗布 |

クライミングスタッフツリーには、ペニスの血管平滑筋を緩めることにより、血行を促進する働きがあるとされており、スムーズな血流の増加によって勃起をサポートします。

ムスクマロウは別名を「ジャコウアオイ」といい、古くから天然の媚薬として用いられてきた歴史があります。性欲を高め、勃起力の向上をサポートします。

| 個数 | 販売価格(1本あたり) | 販売価格(箱) | ポイント | 購入 |

|---|---|---|---|---|

| 1本 | 1,700円 | 1,700円 | 51pt | |

| 3本 | 1,283円 | 3,850円 | 115pt | |

| 5本 | 1,210円 | 6,050円 | 181pt |

①1万円以上で送料無料

1回の注文で10,000円以上だった場合、1,000円の送料が無料となります。

まとめ買いをすると1商品あたりのコストパフォーマンスが高くなるためおすすめです。

②プライバシー守る安心梱包

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

③100%メーカー正規品取り扱い

当サイトの商品は100%メーカー正規品となっており、第三者機関による鑑定も行っております。

商品の破損などがあった場合は再配送などにて対応させて頂きますので、ご連絡頂ければ幸いです。

④いつでも購入可能 処方箋不要

サイト上では24時間いつでもご注文を受けております。

また、お電話によるご注文も受け付けておりますのでネットが苦手な方はお気軽にどうぞ。

⑤商品到着100%

商品発送後はお荷物の追跡状況が分かる追跡番号をご案内させて頂きます。

郵便局には保管期限がありますのでご注意ください。

・自宅配達で不在だった場合の保管期限・・・16日間前後

・郵便局留めとした場合の保管期限・・・7~30日間

⑥コンビニ決済利用可能

ご近所のコンビニにていつでもお支払可能です。

セブンイレブンに限り店舗での機械操作を必要とせず、手続き完了後に表示されるバーコードや払込票番号をレジに提示することでお支払い頂けます。

ヒムコリン 30g x 1本

1,700円

ポイント:51pt

10,000円以上購入で送料無料

在庫あり

飲むタイプのものは副作用が強すぎて利用することが出来ませんでした。どうやら血圧を下げる薬との併用はダメだったみたいです。でもヒムコリンは他の薬との飲み合わせなどは気にする必要がないので安心です。もちろん副作用も出ません。もっと早くヒムコリンを使ってれば良かったです。

天然成分で作られているので体には優しいですが、効き目はありませんね。副作用が心配で避けてきましたが、やっぱりバイアグラやシアリスなのどのED治療薬を使った方がいいかもしれません。

勃起力が弱まっているとか、イマイチ性欲が盛り上がらないときなどに、配合された成分による精力増強に期待できます。成分のひとつであるクライミングスタッフツリーについては血行を促進する働きとともに酸化(老化)防止の働きもあるといわれており、若々しく逞しい勃起力をサポートすると考えられます。

確かに、ヒムコリンには古来“天然の媚薬”として珍重されてきたムスクマロウが配合されているため、性欲を高めることによる性生活の充実が期待できます。

亀頭を避けつつ、ペニスに適量を塗布してください。マッサージをする感覚で塗り込むのがコツです。

女性器には付着しないようにしてください。ヒムコリンを塗ったあとはコンドームを装着することを強く推奨します。

ヒムコリンの使用による副作用の報告はありません。適量を使用する限り、問題なく使用できます。

男性であれば問題なく使用できますが、女性器への使用は安全性が確立されていないため、使わないことが望ましいです。また、特に妊娠中・授乳中の女性は使用できないとされているため、該当する女性との性行為の際は使用を控えることをおすすめします。

| 1日の使用回数 | 1回 |

|---|---|

| 1回の使用量 | 適量 |

| 使用のタイミング | 性行為の直前 |

| 使用間隔 | 指定なし |

| 商品名 | ロイヤルハニー(男性用) | カマグラPOLO | アシュワガンダ | セクシャルピークパフォーマンス | セメナックス | スマートミークリーム | エロクソンスティムゲル | メイルセックスプレジャージェル | コマンドパフォーマンスジェル |

|---|---|---|---|---|---|---|---|---|---|

| 商品画像 |  |  |  |  |  |  |  |  |  |

| 特徴1 | 天然由来のサプリでED改善が期待できる | 水なしで飲める(噛み砕く)チュアブル錠 | ・古くから使われているハーブを配合 | ・EDの改善効果に期待することができる | 男性的な逞しい体づくりをサポート | ・直接塗布して使用するクリームタイプ | ・塗布後10分以内に効果があらわれる | ・ローションタイプで使いやすい男性用媚薬 | ・ED対策にも効果が期待できる |

| 特徴2 | 多彩な成分が多角的に勃起力をサポート! | 2層構造のフレーバーで薬の苦さを軽減 | ・精力増強のほかに多くの健康効果を得られる | ・副作用の心配をせずに摂取できる | 勃起力向上、精液量の増量が期待できる | ・信頼性が高い成分で性機能を改善できる | ・、ローションやコンドームとの併用が可能 | ・ED治療薬を服用できない方も使用可能 | ・即効性があるので速やかな効果を得られる |

| 内容量 | 20g【7月限定特別価格】x12袋 | 100mgx4錠 | 60錠 | 40錠 | 120錠x1本 | 20gx1本 | 4本x1箱 | 30mlx1本 | 35mlx1本 |

| 価格 | 8,000円 | 2,520円 | 2,000円 | 4,400円 | 6,330円 | 5,000円 | 7,600円 | 1,620円 | 3,290円 |

本製品は海外製のため、期限表記が日本と異なる場合がございます。

パッケージ裏面や側面、シートなどに以下のような表記がされています。

| EXP | 使用期限 例:EXP 12/2025→2025年12月まで使用可 |

|---|---|

| MFG または MFD | 製造日 例:MFG 03/2023 |

| BEST BEFORE | 品質が最も安定している目安日 |

※国や製品により日付の並び(例:月/年、日/月/年)が異なる場合がありますのでご注意ください

EXP(Expiry Date) の表記がなく、MFG または MFDしか記載がないケースがあります。

この場合は MFG(MFD) から2~3年が使用期限の目安です。

※「LOT」や「BATCH」の表記は製造番号であり期限ではありません。

パッケージ例となります。

商品やご注文単位によってはシート単位でのお届けとなる場合が御座います。

外箱に当サイト名や商品名が記載されることはないため、ご家族や配達員など第三者に内容を知られることは御座いません。

ED改善系の治療薬を使ったりしたこともありましたが、副作用が辛くて続けるのが無理だったので、今はこれを使わせてもらってます。効果を強く感じるといったことはないですが、以前と比べると立ちは良くなってる気がします。

セックスの前に塗りあげるのがちょっと大変だけど、塗ると塗らないのとでは持続力とかがちょっと違う気がします。ハーブ系の製品なので気のせいかもしれないですけど。

半年ほど前に購入して使うようになってから、徐々に勃起力が高まってきている気はします。ただ、数値的に高まってるみたいなのもないので気のせいかもしれませんが…。

自分はEDって程じゃないからコレでも効き目はあった。ジェルのニオイがちょっと気になるけど、効果的には気に入ってる。

ちょっと下半身が元気になったかな?ってくらい(笑)まぁ、薬は飲むのはちょっと怖いから、当分はこれ使ってみる。

商品口コミの投稿は会員のみ行えるようになっております。

お手数ですが会員ログインの上でご投稿頂きますようお願いいたします。

口コミをご投稿頂いたお客様にはポイントをプレゼントさせて頂いております。

文章のみであれば100ポイント、文章+写真付きのものは300ポイントをプレゼントさせて頂きます。

規約や詳細などはこちらをご確認くださいませ。